Technology for Processing Plantation

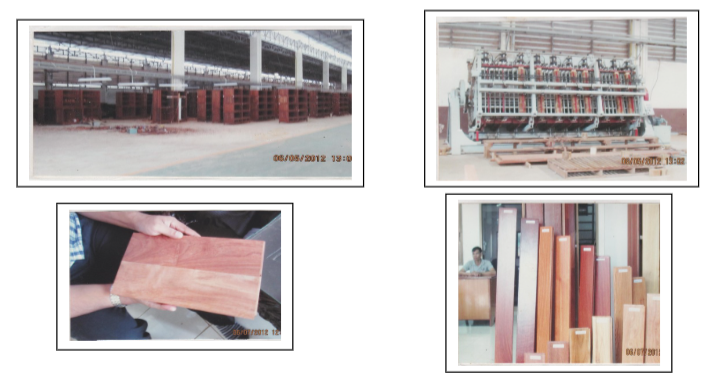

Plantation wood and monocot processing have developed mainly for saving precious natural forests. Processing technology selection of machinery and plant layout etc. could be provided. The processed timber could be utilized for production of construction components, furniture of high aesthetics.

Sophisticated process and plants are available in various countries to process plantation wood and monocots like coconut wood and bamboo.

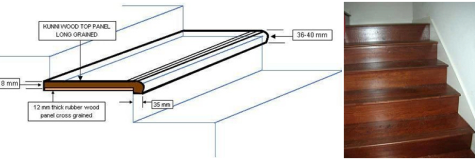

Technology & Process for Production of Prefinished Wooden Staircase steps, Wooden Roof Shingles

Wooden staircase steps are universally accepted because of the foot reaction comfort and antiskid properties. Factory made prefinished staircase steps are extensively utilized in various regions.

Process for developing prefinished staircase step with fixing details could be made available. The top wearing surface could be either in hardwood or in monocots like coconut wood or bamboo.

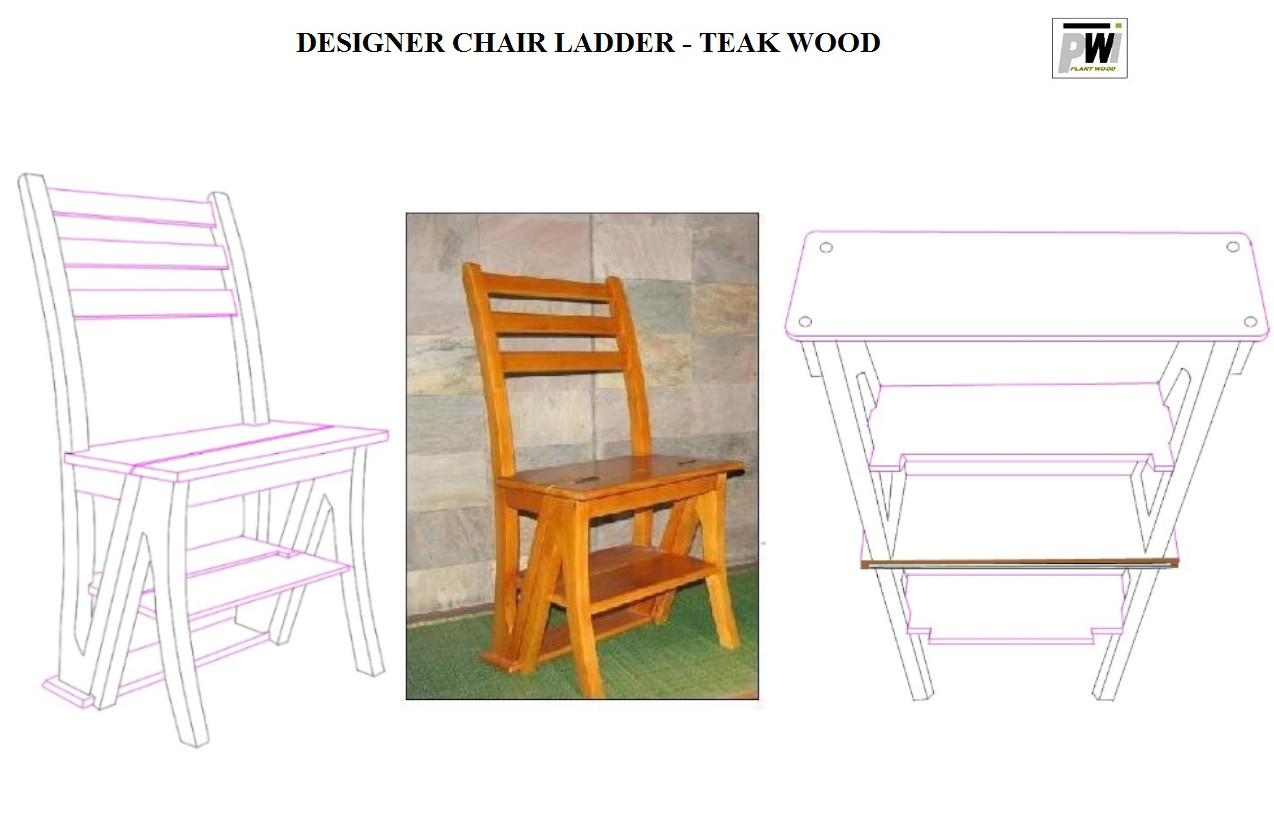

Production of Building Components & Utility Items

Design and process available for certain selected utility items and building components for assembly of homes.

Chair-cum-ladder is a very useful item for households to handle items at a higher level.

Design and process available for production of prefinished walls for structures in resorts and lake side buildings.

Design and process available for production for interlocking solid wood or engineered wood parquet flooring for residences and public places. The unmatched foot comfort offered by wooden flooring is universally accepted.

Parquet Flooring

Wooden Homes and Alternate Panel Homes

The design and process for wooden homes in single and two storeys were developed and details like BAQ and procedure for installation was made available to the clients.

The roof is generally of sloping structure and pile foundations and plinth beams were suggested.

The procedure followed a working module and modular coordination.

The interiors could be installed as per preference of the customer.

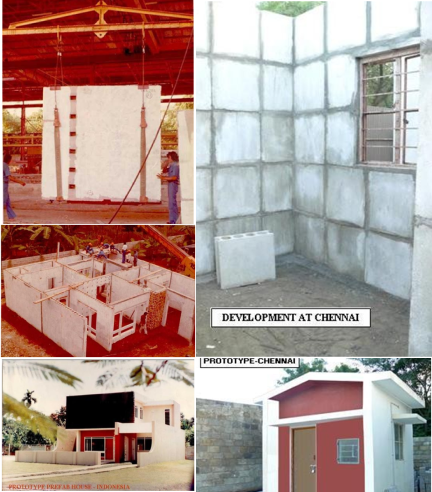

Industrialized Building Systems

A four bedroom prototype residence in two storey was built during 1978-80 period in Indonesia, based on the system developed by consultant Jayabhanu.

System was based on concrete hollow core large panels. The basic structure was erected in three days and the house was completed in all respects within 3-weeks.

Following the basic principles of the system a prototype in concrete hollow core small panels was built in the suburbs of Chennai. The same wet joint was employed in this case also.

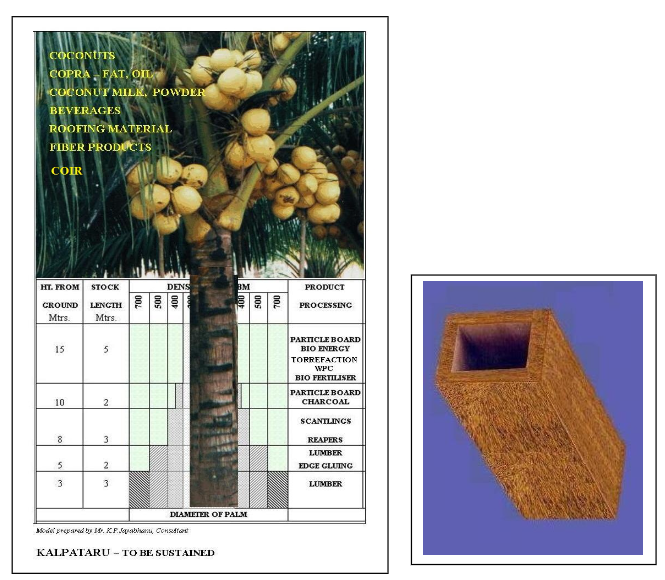

Process of Monocots

Coconut stem from over matured coconut trees with low yield are available in many regions.

The stem could be processed to produce various items. Technology and process are available for utilizing such monocots.

Laminated Door & Window Frames

Laminated door and window frames are popular because of its higher stability and better screw holding qualities. While the outer wood laminates could be of any wood species, the inner core will be with a timber of higher screw holding capacity. The prefinished door and window frames could be an item for many usages.

Wooden Roof Shingles

Wooden roof shingles provide the necessary relief from the monotonous roof structures. Traditionally they are utilized in many regions. Roof shingles could be from selected hardwoods or monocot like coconut wood with back lamination of bitumen impregnated cloth.

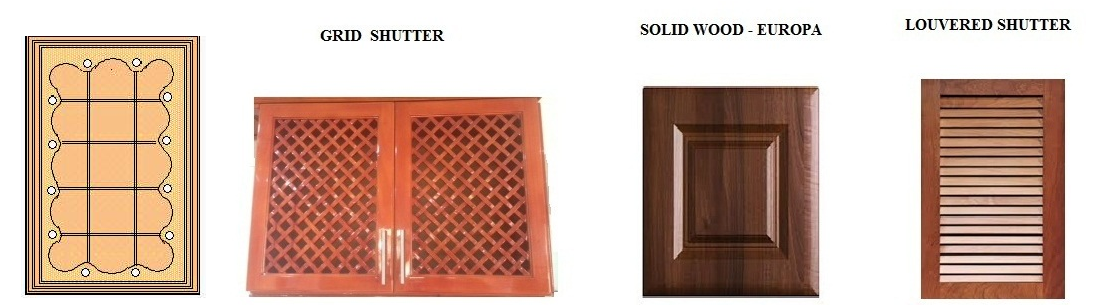

Modular Kitchen and Wardrobes

Modular kitchen systems utilizing solid wood, composite wood panels and other board products incorporating plastic and stainless steel were designed and produced on commercial scale.

The concept is very well established and considerable numbers of companies are operating in this field. System for pre-finished wardrobe units was also established and such an activity led to total solid wood interior solutions.

Wall Paneling

Wall paneling in solid wood, veneer decorative panels or laminated panels could be installed at site as per design and installation instructions.

Acoustic wall paneling also could be designed and details could be provided with installation instruction for music rooms and other areas.

Home Building, Bill of Quantities

Supporting requirements like material specification, BAQ could be made available for various structures complete with plan and perspective view.

These specification and plan are prepared according to the customer requirement and construction. The dimensions shall generally follow the principle of working module and modular coordination.

Process for Production of Surface Profiled Shutters